MAKERS OF CONNECTED OBJECTS

KAERTECH is a Philippine-based company providing full turnkey solutions, offering state-of-the-art product design and advanced manufacturing services. We deliver an all-inclusive solution that covers research and development, engineering, and manufacturing for telecommunication products, multimedia tools, electronic modules, consumer electronics, household appliances, and industrial products.

Our operations are supported by a world-class manufacturing and quality management system, with certifications in ISO 9001, ISO 14001, and ISO 13485, ensuring excellence in quality, environmental responsibility, and medical device manufacturing standards.

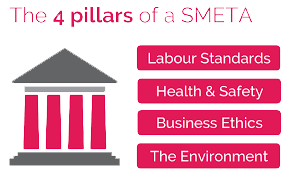

Guided by the four pillars of SMETA—Ethical Trading, Labor Standards, Health & Safety, and Environmental Responsibility—we are committed to responsible business practices, sustainability, and continuous improvement.

Through advanced technology, skilled professionals, and a strong commitment to excellence, KAERTECH delivers innovative, reliable, and globally competitive solutions to meet the evolving needs of our customers.

OUR MISSION

To be a leading provider of innovative, high-quality electronic manufacturing solutions that empower our partners to succeed in the global marketplace. We are committed to delivering exceptional value through cutting-edge technology, sustainable practices, and unwavering dedication to customer satisfaction.

CUSTOMER FOCUS

At KAERTECH, our customers are at the heart of everything we do. We work closely with our partners to understand their unique needs and deliver tailored solutions that exceed expectations. Our commitment to quality, reliability, and innovation ensures that we consistently deliver products that drive success.

WHAT WE OFFER

SYSTEM DESIGN

With system architects on three continents, we work with our customers in the early stages of product development and help them refine product specifications. Beyond product development, we optimize the whole product ecosystem, and help engineer the cloud services, mobile applications and protocols. Where needed, we partner with the bests in the industry to bring state of the art design to life.

ELECTRICAL DESIGN

Our engineers manage all aspects of electrical design, from schematic to board layout. Thanks to years of experience in board design, cutting-edge expertise in Radio Frequency design (Bluetooth, RFID, NFC, WIFI, ANT+, LoRa...) and power and thermal optimization, a close relationship with suppliers and a deep understanding of the integration with mechanical and software design, we have brought to the market some of the most innovative connected devices.

MECHANICAL ENGINEERING

Kaertech's mechanical engineers understand the demands of modern designs. Access to the best suppliers, they work hand-in-hand with our customers to bring their designs to life. We have a deep expertise in plastic molding, metal, CNC, painting, treatment and a long track records of meeting high quality standards and certification while integrating complex mechanisms and stringent cosmetic criteria.

SOFTWARE DEVELOPMENT

We develop embedded software for the products we create. We pride ourselves in writing elegant, robust code. We believe in a tight integration between software, electronic, and mechanical engineering. Our team has been developing embedded software for connected devices for over ten years and is both similar with the leading platforms and flexible to customize solutions for each product. Beyond the device, for the development of mobile applications and cloud services, we work with our partners from Baracoda Group: ALSoft and Flaminem.

QUALITY/ RELIABILITY/ CERTIFICATION

Our quality team manages all aspects of product testing. Test criteria is established in collaboration with our customers and often our quality standards, both in design and in production go beyond our customers' requirements. All test results (temperature and humidity, vibration, drop, IP, ESD, thermal, aging...) are verified independently with third party labs. When the product is ready, we take it through certification on our customer's behalf.

MANUFACTURING

Whether you want to build ten or ten million units Kaertech has you covered. We fully manage board production and SMT and have virtually no capacity limitation. Our state-of-the-art System Assembly facility in the Philippines specializes in high end precision Manufacturing. When volumes are beyond our manufacturing capacity, we work with tier-one manufacturers in Asia. We will smoothly transfer production and all processes to their facility with no downtime and no loss in quality.

VIRTUAL TOUR

- Dedicated Employees: Meet the visionaries behind our success as they bring their passion and expertise to every stage of production.

- Cutting-Edge Equipment: Experience the power of state-of-the-art machinery and robotics, meticulously calibrated to ensure unparalleled precision and efficiency.

- Innovation Hub: Explore our innovation center, where ideas come to life through advanced 3D printing technology and boundary-pushing design.

- Craftsmanship and Quality: Discover the meticulous attention to detail that goes into every component, upheld by our ISO certification and commitment to excellence.

- Sustainability: Witness our dedication to sustainable practices, ensuring minimal environmental impact throughout our manufacturing process.

WHY KAERTECH?

- 14+ years of expertise in wireless, IoT, medical, audio, and AI-enabled smart products

- End-to-end services: product concept, design, and manufacturing

- Philippines-based with strong Western business alignment and Asia market expertise

- Cost advantages from lower tariffs and reduced total cost of goods

- Flexible, high-quality, competitive manufacturing

- World-class manufacturing and quality systems

- Certified to ISO 13485 (medical), ISO 9001, and ISO 14001

ACCREDITATIONS

OUR MILESTONE

Since its inception, Kaertech has achieved numerous milestones in the IoT manufacturing sector in the Philippines. We have launched a wide array of innovative IoT products, expanded our state-of-the-art facilities, and received international certifications for quality and sustainability based on our current milestones. Forming strategic partnerships with global tech leaders has bolstered our technological capabilities and market reach.

MESSAGE FROM THE CEO

Bridging Innovation and Excellence

At KAERTECH, our mission is simple: to transform complex ideas into world-class products through a seamless, end-to-end journey. As the global landscape for technology evolves, the need for a reliable, agile, and ethically-driven manufacturing partner has never been more critical. Since our inception, we have positioned KAERTECH as a premier Philippine-based provider of full turnkey solutions. We don't just offer manufacturing; we offer a partnership that spans the entire product lifecycle—from initial Research & Development and rigorous Engineering to state-of-the-art Manufacturing.

"Our objective is to provide customer with an "all-Inclusive solution" by offering research & development engineering and manufacturing services for telecommunication products, multi-media tools, electronic modules, consume electronic goods, household appliances, and industrial parts."

We recognize that our clients have many choices in the global market. We distinguish ourselves through a steadfast commitment to three core areas:

- Diverse Technical Versatility: Our expertise is broad and deep. From telecommunications and multimedia tools to industrial products and household appliances, we possess the technical infrastructure to handle the most sophisticated electronic modules and consumer goods.

- A Culture of Quality: Quality is the bedrock of our operations. With ISO 9001, ISO 14001, and ISO 13485 certifications, we provide our partners with the peace of mind that their products—including sensitive medical devices—are manufactured to the highest international standards.

- Commitment to Sustainability: We are proud to operate under the four pillars of SMETA. By prioritizing Ethical Trading, Labor Standards, Health & Safety, and Environmental Responsibility, we ensure that your supply chain is as sustainable as it is efficient.

Whether you are looking to scale production or bring a disruptive new technology to market, KAERTECH is equipped with the advanced technology and skilled professionals to make it happen. We invite you to explore how our Philippine-based operations can provide you with a competitive, reliable, and innovative edge in today's fast-paced market.

Thank you for your interest in KAERTECH. We look forward to building the future together.

Mickael Bouffant

CEO & Founder, Kaertech

MESSAGE US

All personal information provided will be collected, used, and processed solely for legitimate business and recruitment purposes. Kaertech ensures that all personal data is handled with strict confidentiality and in accordance with applicable data privacy laws. Personal information will not be shared with unauthorized parties and will be securely stored to prevent unauthorized access.

By submitting your personal details, you consent to the collection and use of your information for the purposes stated above.